The following article may be used free of charge with no prior authorization provided that it is used for nonprofit purposes and appears with the author biography at the end of this article intact. Please email us with any details of its use so that we can keep the author or other interested parties informed of the use of this article.

HAYING IN OLD GILBOA

Carlton Lewis

I remember seeing a painting of hay in stacks in the field, and each stack had been combed with a pitchfork to make its own thatched roof. I also have been told that patents for hay presses and baling equipment had been granted starting in the early 1800s, and I remember seeing a stationary baler driven by a gas engine — you would gather the loose hay and feed it into the baler, then move the bales into the barn. However, these advances were denied me in my Wyckoff Road youth where we cut and stored only loose hay.

Today, people cannot imagine the back-breaking work involved in "making hay." We will discuss the labor involved in cutting hay, drying it thoroughly, loading it onto wagons, getting it to the barn, loading it in the loft, and still having the time and energy to feed all the animals and milk the cows both before and after the day’s haying on the sunny days of midsummer. And remember, if your hay gets rained on or absorbs morning dew, you have to go through the entire process again. This is the source of the folk saying, Make Hay while the Sun Shines!

In the 1930s, Gilboa labor was cheap while equipment was expensive. We used a simple horse-drawn sickle bar to cut the hay and a drop rake to create piles of hay. We didn’t spend money on a specialized cutter to create swaths or the side delivery rake to automatically turn the hay for drying. We used our own arms to turn the hay for drying, ending with a field covered by small piles of relatively dry hay.

The hay wagons we used to collect the hay had 4' iron wheels and an adjustable iron frame, on which we had built a sturdy platform about 14' long and 8' wide. My brother and I would walk along on either side of the wagon, and fork the hay up to my father; he would both drive the horses and pack the hay into a tight bulk. The first hay would be thrown into the corners of the wagon and firmly trampled down. Subsequent forkfuls would tie the corners together and finally cover the center of the wagon. This would continue until we couldn’t throw the hay up to the top — possibly 8' on the wagon and 12' above the ground. The hay itself would be a solid cube, 8' x 14' x 8' and well packed for easier unloading in the barn. We would then drive this wagon to one end of the barn.

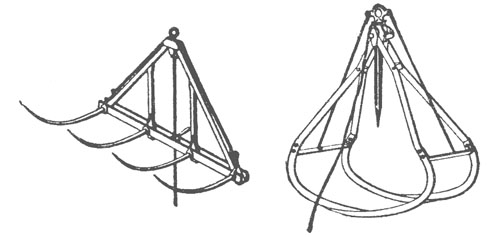

On smaller farms such as ours, the ridgepole of the barn extended out from the barn and the roof also overhung it enough to protect both the ridgepole and the large door below it. There was a winch bolted to floor at this end of the barn, and an iron track was hung below the ridgepole all the way to the other end of the barn (this track might also have branches going to other areas in larger barns). A heavy steel carriage rode on this track and could be rolled above the entire hay storage area. A rope, attached to the winch, was long enough to run up over a pulley on the carriage and back down to the wagon. The rope had a large hook to attach a hay fork that came in a variety of styles: single harpoon (or shear fork), double harpoon fork, derrick forks, and four-, six-, and eight-tined grapple forks.

The use of a particular hay fork was largely determined by the size of the opening through which the loaded fork would have to fit. In Gilboa, the prevalent barns had doors similar to ours — less than 1o' wide — so that the double harpoon fork seemed to be the standard (a double harpoon could bite nearly the 8' width of a haywagon). Thus, three bites from a double harpoon would be sufficient to remove the top half of the wagon’s load; three more bites would lift the majority of the second level; and any remaining hay would go in a final bite by the double harpoon. We also used small grapple forks as well.

Larger barns were constructed so that horses could pull the fully loaded hay wagons up an inclined plane onto the haymow [second] level of the barn. Without having to fit the hay through small doors, much larger forks like derricks and grapples could be used to take huge bites and really ease the storage of hay. Another solution was the use of a hay sling: two nets clipped together in the middle with rings at either end is laid like a hammock on the bed of the wagon. Once in the barn, the net containing the entire load would be hooked to the block and tackle, lifted to its final position, and dropped.

| I used the dump rake to gather the hay into long, flat piles. Later that same day, we could turn the hay and place it in more compact piles for loading onto the wagons. |

| This crew was our neighbor Frank Brown (the owner of the Flat Creek Gristmill), his grandson Franklin, my dad, and me. Once in a while, we saw "hay devils” — small wind funnels that would pick up the raked hay and drop it everywhere so that you had to start the entire field again. Another source of grief was bees that loved to nest in the fields. |

|  |  |  |

| Single (1, 2) and double (3, 4) harpoon forks. The long tines of the fork would be driven deeply down into the hay, and then the spikes (2, 4) would be driven horizontally into the heart of the hay, keeping the hay and fork as a single unit. Photos courtesy of the Gilboa Museum. |

|  |

| Above, a 4-tined grapple fork and a derrick fork; right, a hay sling with a spring catch in the middle to release the hay. Photo courtesy of Davidson and Chase: Farm Machinery by Lyons Press. |

Rianna Starheim wrote about South Gilboa’s Decker-Starheim barn in the Summer 2006 GHS Newsletter. This ingenious design combined a ramp going to the top of the barn well above the hay storage area and pivoting hay wagons. The farmer would drive the wagon into the barn and simply dump the entire load at one time.

Carlton Lewis, a dairyman for nearly 30 years, changed careers to become a master machinist in the early 1970s. At that time, the dairy industry in the Catskills had fallen on hard times, all creameries were cutting back, and the closing of Blenheim Creamery spelled the end for the 500 dairy farms that it served — including Carlton’s.

Carlton Lewis, a dairyman for nearly 30 years, changed careers to become a master machinist in the early 1970s. At that time, the dairy industry in the Catskills had fallen on hard times, all creameries were cutting back, and the closing of Blenheim Creamery spelled the end for the 500 dairy farms that it served — including Carlton’s.

To use this article in your newsletter or as a handout, click into the article; select all; copy; and paste into a MSWord file.

Please remember to let us know of this use so that we can let the author or other interested parties know.

To subscribe or unsubscribe to this site, click here and select northerncatskillhistory (top left link).

Fill in your email address, name (optional), and a simple password.

You will receive an email confirming your intent

Respond to it to subscribe or unsubscribe to northerncatskillhistory.com

November 13, 2010

Copyright © 2009

northerncatskillshistory.com

contact northerncatskillshistory.com

![]()